Feature RSL200

•Laser cut heavy steel frame with thorough powder-coating

•Extreme craftsmanship and operational experiences

•Processing edges needs to be as quick,easy and efficient as possible

•That fulfil the ever Increasing demands of edge banding complete processing

•Constantly high performance in Industrial continuous operation

•Solid design with premium components

•Complete engineering precision

•CE approved

Edge Banding Machine RSL200 | |

Edge thickness | 0.3-3mm |

Panel thickness | 15-50mm |

Power | 750W |

Feeding speed | 2-6m/min |

Arc diameter | >=40mm |

Diemensions | 465*430*510mm |

Weight | 10KG |

1. Stepless speed regulation

Use the stepless speed regulation function to slow down the speed to realize the curved and straight edge banding of various special-shaped plates.

2.Standard workbench

The workbench is made of wood panel, which is wear-resistant and does not deform. When sealing small plates, the plates can be placed on the workbench and the plates are pushed for edge sealing.

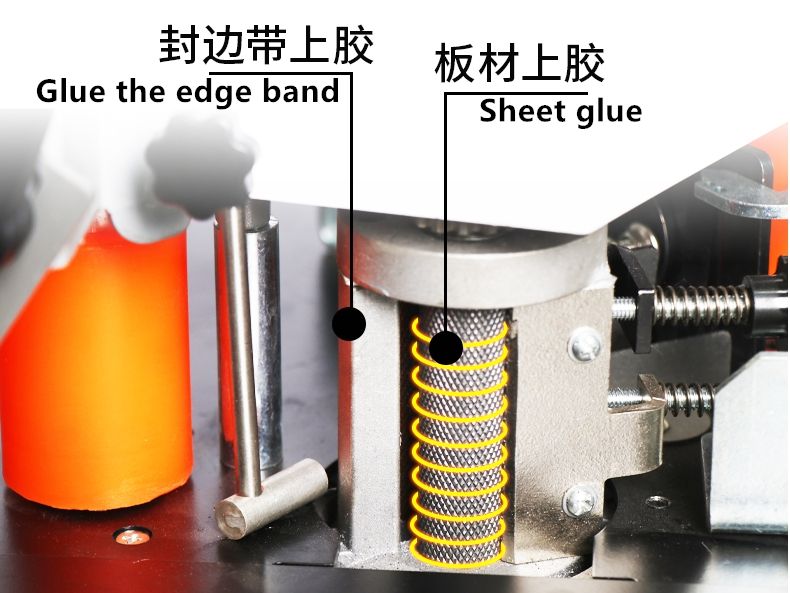

3.Double-sided gluing, the glue pot never leaks

Adopt double-sided gluing system and enlarge the glue pot, suitable for most plates.

4. Can seal 60mm wide edge banding

Solved the problem that thickened plates can only be manually sealed.

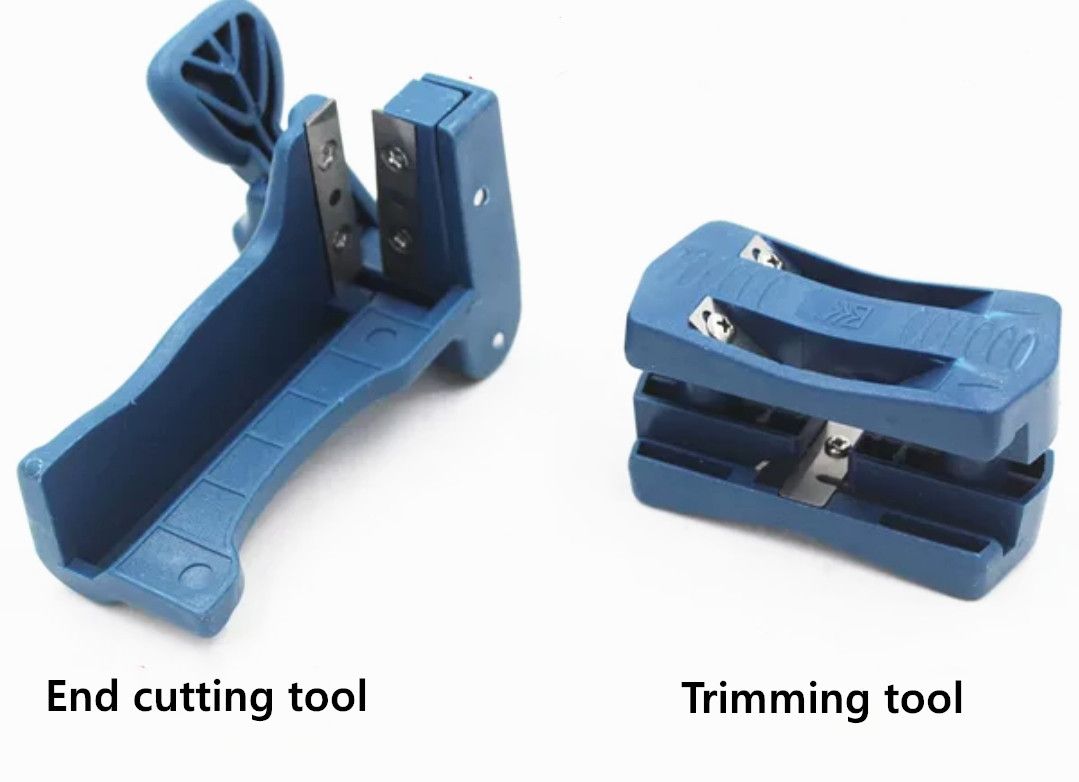

End cutting, trimming tools: